About my process

Mining in Grawin

We bought our mine in Grawin opal fields in 2004 when we lived in Lightning Ridge, 80 km. East of Grawin. We bought the 50x50 meter mine plot from 4 acquaintances who were getting old and ready to retire.

In Grawin, the opals are formed in seams in a clay layer under a layer of sandstone. The clay layers can occur from just below the surface to a depth of 30 meters. Most mines have one to three opal-bearing layers. In our mine we have 2 layers, and we dig in one that is 15 meters underground.

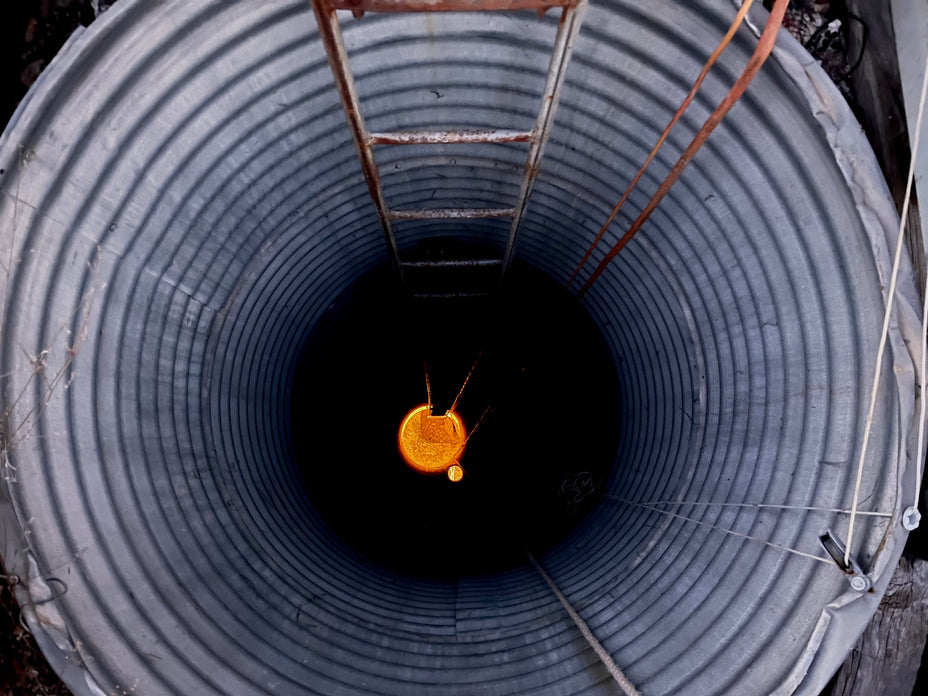

How to get down into the mine

The mine entrance is a hole about 1 meter in diameter with a vertical ladder that leads down to the mine passages. The ladder is also part of the hoisting mechanism that is used to get the soil out of the mine.

Power to the mine

Out in the mining areas there is no electricity, so we have a 30 kW diesel generator standing on top of the mine. It produces power for all our machines and lights. It is our most important machine – without it nothing works and the work comes to a standstill.

Excavation of the opals

Down in the mine we dig tunnels with our hydraulic excavator (digger) which has two feet that go down into the floor and a cylinder that goes up into the ceiling to hold it in place. The thick layer of sandstone above our heads makes the mine strong and stable. Then we can dig out the earth with the small shovel on the excavator.

The opals are then formed in layers under the sandstone. If we are lucky enough to find some thin veins of opal, we try to follow it and hope that it becomes thick enough for opals to form. If we are really lucky, there may also be noble opal, which would mean that the opal has a play of colors.

Our next challenge is to get the opals out in as large pieces as possible without damaging them. If possible, we try to remove the soil around the opal-containing soil. We then lay a tarpaulin on the ground and try to bring as large pieces down onto the tarpaulin as possible so that we can then sort them.

If there is not enough space for the excavator, it is sometimes easier to grab the jackhammer or pickaxe and dig out the last bit by hand.

Disposal of surplus soil

The Bogger

We remove the loose excess soil that lies in front of the excavator with a 'bogger'. It is a kind of hydraulic wheelbarrow with a shovel that can load the soil into itself. Each load contains approximately 300 kg of soil, which we then drive to the hoist. At the back of the bogger there is a door that we open, after which we lift the container up so that the soil can fall into the bucket on the hoist.

Disposal of surplus soil

The hoist

The hoist is probably the most dangerous part of the mining operation. There are many moving parts and many tons of soil that have to be lifted out of the mine every day. A full bucket of soil weighs approximately 200kg and has to travel 20 meters up the ladder before it is unloaded into the truck. Originally everything was electrically controlled but after the control equipment and motor were stolen we have switched to old-fashioned manual operation.

Disposal of surplus soil

The truck

After the hoist has delivered about 6 tons of soil to the truck, it must be emptied. Any excess soil must be taken to designated waste sites to avoid poluting the mine area. On a normal working day, we fill the truck twice.

It may look a little worn, but it's actually the most reliable equipment we have.